Dear My Friend, |

First

your should read and understand what is the clean drinking water. We

know about drinking water much important for our body to continue our

live. As one of the greatest solvents

known, water helps prepare substances for transport across cell

membranes and for distribution through our bodies by way of blood and

lymph. This function of water in our bodies is impaired when the water

is filled with contaminants that interfere with its ability to dissolve

bodily substances efficiently.

Within the body, water acting as a solvent, reaches into every cell to absorb and carry away the poisons that are formed as a part f the life process. Lots of pure water is needed for his task. We all know that it is easier to wash dishes in a sink full of clean water than in a cup full of dirty water. The blood circulates 400 gallons of water through the kidneys each day. Common sense tells us that when water we consume is pure, it can do a much better job than when it is already contaminated with toxic substances. |

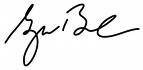

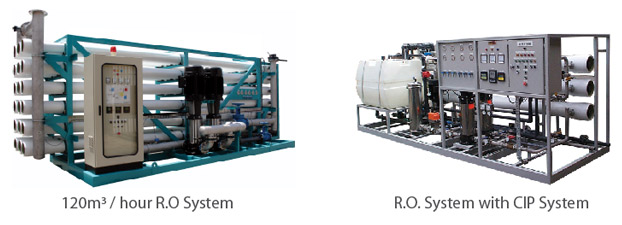

Reverse osmosis (RO) is the most popular water treatment system in today’s market. Due to it's cost effectiveness, quality reliability, minimum operation supervision, less energy consumption and minimum chemical dosage compare to other water treatment methods such as distiller and water demineralization.

RO is one type of membrane separation technology which utilized membrane pressure differential to separate raw water from stronger solution to the weaker. It is suitable to treat almost all kind of raw water such as well water, stream water, river water, rain water, tap water (brackish water) and sea water. In general, it is the most economical process for desalination of brackish water and sea water. It has no hazardous chemical handling and suitable for clean environment.

An optimum RO system would improve the performance, ease of operation and ultimately reduce operating cost. HD Tech’ technical staffs are specializing in water treatment technologies in their respective specialties. Together, they had been involved in many custom-designed RO plants, and are capable to design, fabricate, install and commissioning RO system up to 10,000m³/day.

The membranes used for reverse osmosis have a dense barrier layer in the polymer matrix where most separation occurs. In most cases the membrane is designed to allow only water to pass through this dense layer while preventing the passage of solutes (such as salt ions). This process requires that a high pressure be exerted on the high concentration side of the membrane, usually 2–17 bar (30–250 psi) for fresh and brackish water, and 40–70 bar (600–1000 psi) for seawater, which has around 24 bar (350 psi) natural osmotic pressure which must be overcome.

This process is best known for its use in desalination (removing the salt from sea water to get fresh water), but it has also been used to purify fresh water for medical, industrial and domestic applications since the early 1970s.

Osmosis describes how solvent moves between two solutions separated by a semipermeable membrane to reduce concentration differences between the solutions. When two solutions with different concentrations of a solute are mixed, the total amount of solutes in the two solutions will be equally distributed in the total amount of solvent from the two solutions. Instead of mixing the two solutions together, they can be put in two compartments where they are separated from each other by a semipermeable membrane. The semipermeable membrane does not allow the solutes to move from one compartment to the other, but allows the solvent to move. Since equilibrium cannot be achieved by the movement of solutes from the compartment with high solute concentration to the one with low solute concentration, it is instead achieved by the movement of the solvent from areas of low solute concentration to areas of high solute concentration. When the solvent moves away from low concentration areas, it causes these areas to become more concentrated. On the other side, when the solvent moves into areas of high concentration, solute concentration will decrease. This process is termed osmosis. The tendency for solvent to flow through the membrane can be expressed as "osmotic pressure", since it is analogous to flow caused by a pressure differential.

In reverse osmosis, in a similar setup as that in osmosis, pressure is applied to the compartment with high concentration. In this case, there are two forces influencing the movement of water: the pressure caused by the difference in solute concentration between the two compartments (the osmotic pressure) and the externally applied pressure.

WHO Guidelines for drinking-water quality

Drinking-water quality is an issue of concern for human health in developing and developed countries world-wide. The risks arise from infectious agents, toxic chemicals and radiological hazards. Experience highlights the value of preventive management approaches spanning from water resource to consumer. WHO produces international norms on water quality and human health in the form of guidelines that are used as the basis for regulation and standard setting, in developing and developed countries world-wide.

You can click link below for detail:

Water Safety plans by WHO

Drinking Water and Guideline by WHO

HD Tech's Packaging Equipment Area

Automatic Bottle Filler & Capper

* Up to 1500 bottles per hour

* Compact Design

* Stainless Steel Construction

* Pneumatically operated

* Economical

* Versatile

Unskilled operator can easily fill and cap as many as 1500 bottles per hour, with computer-controlled accuracy and efficiency. To enhance the performance and value, an optional automatic labeler, rinser and date coder are available.

Specially engineered to eliminate the need for highly trained operators or service personnel. The conveyor speed (bottling rate) is adjustable and can be set to accommodate operator proficiency, allowing new operators to start out slowly and increase their speed as they become more experienced.

My friend,

We can work together if you like to be one of our members SME project "drinking water in bottle". We can help you from A to Z how to manufacturing drinking water in bottle. You would be compensated on the equipment you need. We need to determine what your expectations, budget and volume would be for the facility. Above picture and text will help you to getting started.

If you have any questions please contact me. Thank you. Very Very Best Regards, |

|

|

|